Taking your molded part to a fully-functional finished piece, saving you time and money.

Value-added assembly is the process of putting together smaller components before they are added to a final product. Outsourcing assembly to another company can allow a manufacturer to focus more on its core processes. It can also help a company grow without adding space or expanding employment.

Contact us to learn how value-added assembly can help you control costs and build more profitability into your products.

Why Use Metalcraft Plastics Group for Value-Added Assembly?

When you use Metalcraft Plastics Group for assembly, you're receiving a turnkey solution that results in the delivery of a finished product. There are several advantages to this business strategy.

By consolidating production, assembly and logistics with Metalcraft Plastics Group, you can add efficiencies that help decreased lead times and faster speed to market.

Value-added assembly can reduce overall cost by freeing up cash that was formerly tied to holding inventory.

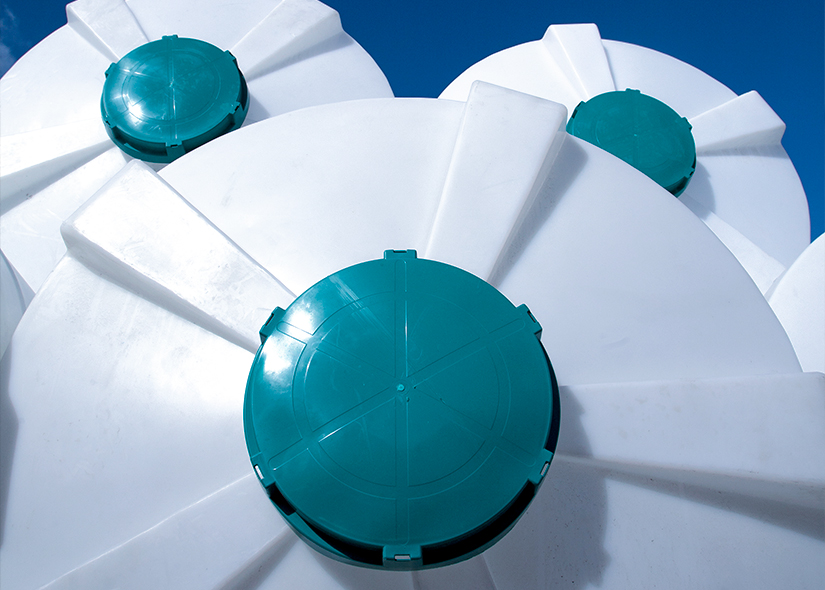

Tank cleanliness is highly important, especially when it comes to hydraulic tanks. When tanks are fully assembled in our facility, you can be assured that tank cleanliness is preserved.

By consolidating your production and assembly into a single supplier, you reduce your points of contact to just one. This allows you to receive a more customized level of service.

When tanks are fully assembled at Metalcraft Plastics Group, we can also conduct leak testing right here. That's one more function you won't have to handle.

© Metalcraft of Mayville. All Rights Reserved.